Fashion and Sustainability: How Much Do You Know About Eco-Friendly Fabrics?

In today's fast-fashion world, the apparel industry has become the second-largest polluter globally, second only to the oil industry. Approximately 92 million tons of textiles are landfilled or incinerated annually, and the production of a typical cotton T-shirt consumes 2,700 liters of water—equivalent to three years' worth of water for a person. Faced with these environmental pressures, eco-friendly fabrics have emerged, aiming not only to reduce the fashion industry's burden on the planet but also to redefine our relationship with clothing.

Traditional natural fibers like cotton, while naturally derived, often come with significant ecological costs during their cultivation. Globally, cotton cultivation occupies 2.5% of arable land but consumes 16% of pesticides. In contrast, organic cotton significantly reduces soil and water pollution by prohibiting the use of genetically modified seeds and toxic chemicals, but water consumption remains high. Another natural fiber garnering significant attention is hemp (such as flax and hemp). These fibers grow quickly, require virtually no pesticides, and the entire plant is usable. However, their fibers are coarser and not as soft as cotton. Bamboo fiber is often touted as "natural and environmentally friendly," but the reality depends on how it's processed. Some bamboo fibers use a chemical dissolution process similar to viscose, which can be polluting, while mechanically processed raw bamboo fiber is more sustainable.

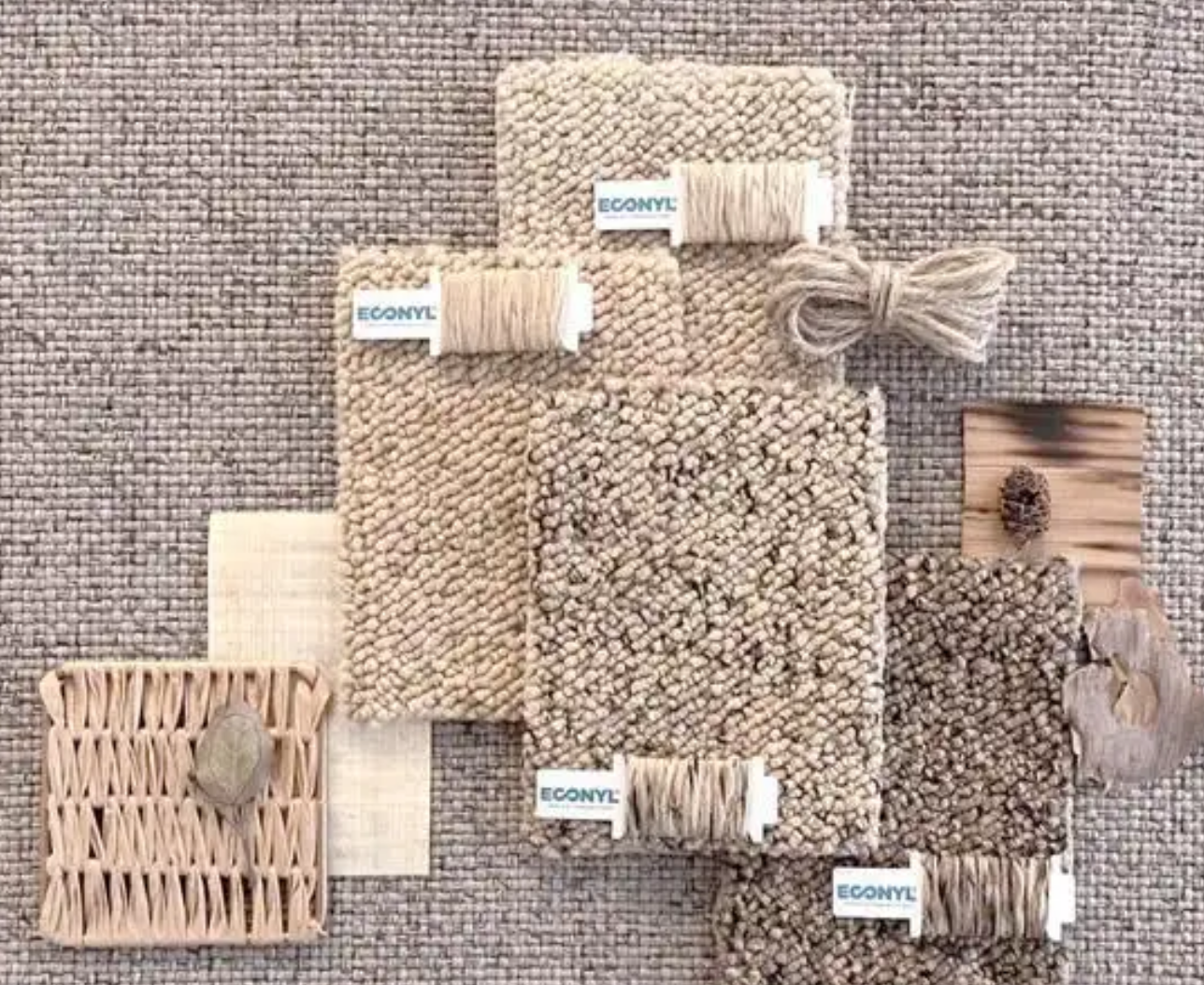

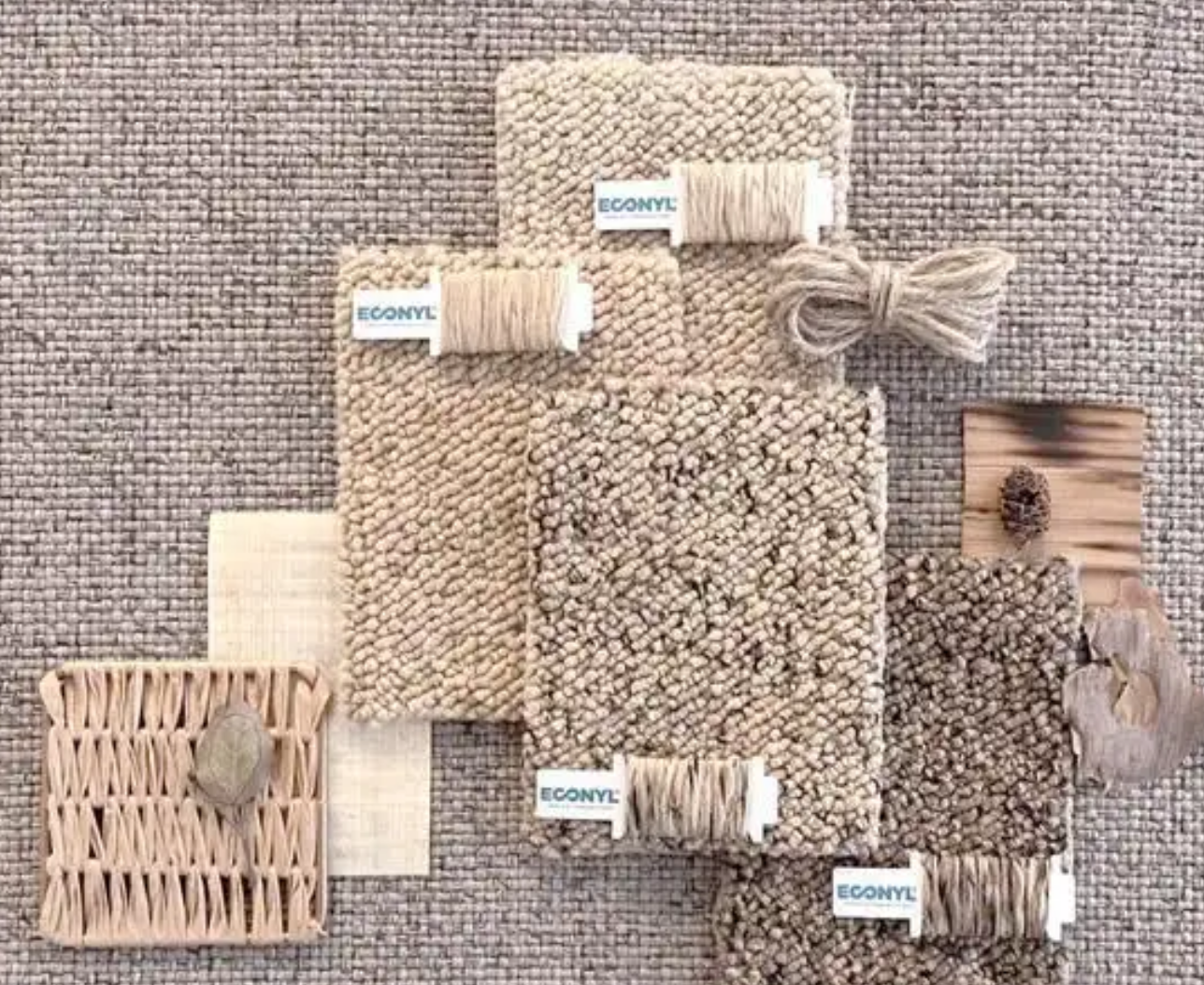

In the field of recycled fibers, technology is creating surprising solutions. Recycled polyester (rPET) converts discarded plastic bottles into new fiber through melt spinning. Each ton of rPET reduces oil consumption by 3.8 barrels. Adidas and Parley's sneakers use an average of 11 recycled plastic bottles per pair. Lyocell represents a more advanced environmental technology. Made from eucalyptus pulp, it's produced in a closed-loop system with over 99% solvent recovery, resulting in 50% lower carbon emissions than traditional viscose. TENCEL™ branded Lyocell fibers are widely used in high-end fashion and bedding, demonstrating that environmental sustainability and quality can be achieved simultaneously.

In the field of recycled fibers, technology is creating surprising solutions. Recycled polyester (rPET) converts discarded plastic bottles into new fiber through melt spinning. Each ton of rPET reduces oil consumption by 3.8 barrels. Adidas and Parley's sneakers use an average of 11 recycled plastic bottles per pair. Lyocell represents a more advanced environmental technology. Made from eucalyptus pulp, it's produced in a closed-loop system with over 99% solvent recovery, resulting in 50% lower carbon emissions than traditional viscose. TENCEL™ branded Lyocell fibers are widely used in high-end fashion and bedding, demonstrating that environmental sustainability and quality can be achieved simultaneously.

Even more revolutionary are bio-based innovative materials. Mushroom leather uses mycelium to "grow" a leather alternative in just two weeks, eliminating the need for animal farming and tanning pollution and producing only 10% of the carbon emissions of animal leather. Piñatex®, a pineapple leaf fiber, is extracted from agricultural waste, using 480 pineapple leaves per square meter, generating additional income for farmers. While these materials are currently relatively expensive (mushroom leather is twice as expensive as genuine leather), they are gradually entering the mainstream market with technological advancements and scale-up.

However, environmentally friendly fabrics still face numerous challenges. Recycling blended fabrics is a major challenge—cotton and polyester blends are difficult to separate effectively, and only 13% of textiles are actually recycled globally. Some polyester fibers advertised as "biodegradable" require specific industrial conditions to break down and may be as durable in the natural environment as traditional plastics. Even more insidious is the phenomenon of "greenwashing," where some brands mislead consumers with vague environmental claims, such as advertising "bamboo fiber" without disclosing the use of polluting chemical processes.

As consumers, we can drive industry change through several key actions: prioritize products with certifications like GOTS (Global Organic Textile Standard) and GRS (Global Recycled Standard); extend the lifespan of clothing, as studies show that every nine extra months of wear can reduce carbon footprints by 20%-30%; and support brand take-back programs, such as Patagonia's Worn Wear program, which offers repair and buyback services for used clothing. The EU's upcoming "Textile Strategy 2030," which requires all textiles to be labeled as recyclable and limits the release of microplastics, will accelerate industry transformation.

As consumers, we can drive industry change through several key actions: prioritize products with certifications like GOTS (Global Organic Textile Standard) and GRS (Global Recycled Standard); extend the lifespan of clothing, as studies show that every nine extra months of wear can reduce carbon footprints by 20%-30%; and support brand take-back programs, such as Patagonia's Worn Wear program, which offers repair and buyback services for used clothing. The EU's upcoming "Textile Strategy 2030," which requires all textiles to be labeled as recyclable and limits the release of microplastics, will accelerate industry transformation.

The ultimate purpose of sustainable fabrics isn't to create perfect solutions, but to move the entire system from a linear "take-make-discard" model to a circular economy. When a swimsuit made from recycled fishing nets, a handbag "grown" from mycelium, or a polyester jacket recycled ten times becomes an everyday item, what we wear becomes more than just clothing; it becomes a commitment to the future.